Enhance your industrial floors with advanced coatings like epoxy, urethane, or MMA for durability and safety. These coatings protect against wear, chemicals, and spills, extending floor lifespan. Choose based on specific needs like strength, UV stability, or rapid cure times. Consider environmental factors, traffic levels, and maintenance requirements when selecting the right coating. Follow proper installation and maintenance guidelines to ensure longevity. Real-world case studies highlight the benefits of industrial floor coatings in various settings. Discover how these solutions can elevate your floors to meet specific industrial demands.

Benefits of Industrial Floor Coatings

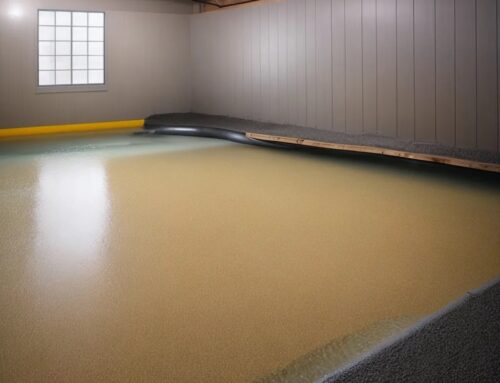

Discover the myriad advantages of industrial floor coatings, essential for enhancing durability and safety in various work environments. When considering industrial floor resurfacing versus coating, opting for coatings proves to be a more cost-effective and efficient solution. Industrial floor coatings provide a protective layer that not only enhances the appearance of the floor but also adds a durable shield against wear and tear, chemicals, and spills. This protection prolongs the lifespan of the floor, reducing the need for frequent repairs or replacements.

Choosing the best type of coating for industrial floors is crucial in ensuring optimal performance. Epoxy coatings are a popular choice due to their high durability, chemical resistance, and easy maintenance. Urethane coatings offer excellent abrasion resistance, making them suitable for heavy-traffic areas. MMA coatings, known for their fast curing times, are ideal for facilities requiring quick turnaround times.

When seeking industrial concrete floor coating companies, it is essential to partner with experienced professionals who understand the specific needs of industrial environments. These companies can provide expert advice on the most suitable coatings for your facility, ensuring a long-lasting and high-performance flooring solution. By investing in industrial floor coatings, you not only enhance the durability of your floors but also improve safety standards in the workplace.

Types of Coating Systems

Various types of coating systems are utilized in industrial settings to provide superior durability and protection for floors. Epoxy coatings, known for their exceptional strength and chemical resistance, are a popular choice. They form a hard, glossy surface that can withstand heavy foot traffic and machinery. Urethane coatings, on the other hand, offer excellent abrasion resistance and UV stability, making them ideal for outdoor applications or areas exposed to sunlight. Additionally, urethane coatings provide enhanced protection against harsh chemicals and oils.

Methyl methacrylate (MMA) coatings are another option known for their rapid cure time, allowing for quick return-to-service. These coatings are often used in environments where downtime must be minimized. MMA coatings offer high impact resistance and durability, making them suitable for high-traffic areas.

Polyaspartic coatings are gaining popularity due to their fast cure times and excellent UV stability. They provide a high-gloss finish and are resistant to yellowing, making them a great choice for areas that require a visually appealing surface.

Each type of coating system offers unique advantages, so selecting the right one depends on factors such as the environment, traffic levels, and specific requirements of the facility. It is essential to consider these factors when choosing the most suitable coating system for your industrial floor.

Factors for Choosing the Right Coating

When selecting the appropriate industrial floor coating, consider factors such as environmental conditions, traffic volume, and specific facility requirements to ensure optimal performance and longevity. Environmental conditions play a crucial role in determining the type of coating suitable for your industrial floor. For instance, if your facility is exposed to high levels of moisture or chemicals, epoxy coatings might be the best choice due to their excellent chemical resistance and durability. On the other hand, if your facility experiences extreme temperature fluctuations, polyurethane coatings can provide the flexibility needed to withstand such conditions.

Traffic volume is another essential factor to consider when choosing the right coating. High-traffic areas require coatings that are abrasion-resistant and can withstand constant wear and tear. For such environments, MMA (methyl methacrylate) coatings are a popular choice due to their rapid cure time and high durability.

Specific facility requirements, such as anti-slip properties, UV resistance, or ease of maintenance, should also be taken into account. For areas where slip resistance is crucial, adding aggregates to the coating can enhance traction. UV-resistant coatings are ideal for outdoor areas exposed to sunlight to prevent color fading and degradation. Additionally, selecting low-maintenance coatings can reduce long-term upkeep costs and ensure the longevity of the floor system. By considering these factors, you can choose the right industrial floor coating that meets your facility’s unique needs and ensures long-lasting performance.

Installation and Maintenance Guidelines

For efficient installation and long-term durability, adhere strictly to the recommended guidelines for industrial floor coating application and maintenance. Proper surface preparation is crucial before coating application. Ensure the substrate is clean, dry, and free of any contaminants that could affect adhesion. Repair any cracks or imperfections in the concrete to create a smooth base for the coating.

When applying the industrial floor coating, follow the manufacturer’s instructions regarding mixing ratios, application temperatures, and curing times. Use the appropriate tools, such as rollers or squeegees, to achieve an even and consistent coat. Work in sections to maintain a wet edge and prevent lap marks.

After the coating has been applied, allow sufficient time for it to cure before subjecting it to heavy traffic or chemical exposure. Regular maintenance is key to prolonging the life of the coating. Clean the floor regularly using a neutral pH cleaner and avoid harsh chemicals that could degrade the coating.

Inspect the floor periodically for any signs of wear or damage, and address issues promptly to prevent further deterioration. By following these installation and maintenance guidelines diligently, you can ensure the longevity and performance of your industrial floor coating.

Case Studies and Success Stories

Exploring notable instances of industrial floor coating applications unveils the transformative impact of advanced solutions like epoxy, urethane, and MMA in real-world settings. One compelling case study involves a manufacturing facility that upgraded its floors with epoxy coatings, resulting in a significant reduction in maintenance costs and downtime. The seamless and durable epoxy surface not only enhanced the aesthetic appeal of the facility but also provided a safer working environment by improving slip resistance and chemical resistance.

In another success story, a food processing plant implemented urethane floor coatings to meet stringent hygiene standards. The seamless and non-porous nature of urethane coatings prevented bacterial growth, ensuring food safety compliance. Additionally, the exceptional impact resistance of urethane coatings proved vital in withstanding heavy equipment and constant foot traffic without compromising the floor’s integrity.

Moreover, a warehouse facility experienced remarkable results after applying MMA coatings to its floors. The rapid curing time of MMA coatings minimized operational disruptions, allowing the facility to resume activities quickly. The high chemical resistance of MMA coatings also protected the floors from corrosive substances commonly found in warehouse environments.

These case studies demonstrate the diverse applications and benefits of advanced industrial floor coatings, showcasing how epoxy, urethane, and MMA solutions can elevate the functionality, durability, and safety of commercial spaces.

Key Takeaways

- Industrial floor coatings enhance durability and safety in work environments.

- Coatings provide a cost-effective and efficient solution compared to resurfacing.

- Different coatings like epoxy, urethane, and MMA offer specific benefits.

- Factors for choosing the right coating include environmental conditions and traffic levels.

- Proper installation and maintenance are crucial for maximizing the lifespan of industrial floor coatings.