To protect steel in industrial settings, choose durable epoxy paint solutions. Benefit from enhanced durability and corrosion resistance. Ensure proper surface prep for optimal results. Opt for epoxy with excellent adhesion for a strong bond. Industrial floor coating boosts resistance to wear, chemicals, and moisture. Maintain safety with proper ventilation and protective gear. Select epoxy based on specific industrial needs like chemical or heat resistance. Thoroughly prepare the surface for effective adhesion. Regular maintenance and cleaning extend the coating’s lifespan. Discover more about epoxy benefits for steel surfaces.

Benefits of Epoxy Paint for Steel

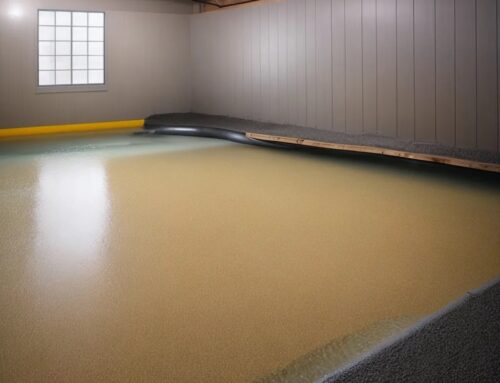

Protecting steel surfaces with epoxy paint enhances durability and resistance against corrosion and wear. When considering the best epoxy paint for steel floors, it is crucial to understand the process of how to paint steel with epoxy for optimal results. Industrial floor coating for steel requires specific considerations to ensure a long-lasting finish that can withstand harsh industrial environments.

The best epoxy paint for steel floors is one that offers excellent adhesion properties to ensure a strong bond between the paint and the steel surface. Proper surface preparation, including cleaning and roughening the steel, is essential to promote adhesion. Additionally, choosing an epoxy paint specifically formulated for steel surfaces can enhance the overall performance and longevity of the coating.

To paint steel with epoxy effectively, it is important to follow the manufacturer’s instructions regarding mixing ratios, application methods, and curing times. Proper application techniques, such as using rollers or brushes designed for epoxy coatings, can help achieve a smooth and even finish. Ensuring thorough coverage and avoiding over-application can prevent issues such as bubbling or uneven drying.

Industrial floor coating for steel provides a protective barrier that not only enhances the appearance of the surface but also increases its resistance to abrasion, chemicals, and moisture. By selecting the right epoxy paint and following proper application procedures, you can significantly extend the lifespan of steel surfaces in industrial settings.

Safety Measures for Epoxy Application

Ensure proper ventilation and use protective gear when applying epoxy to prioritize safety during the application process. Ventilation is crucial to prevent the inhalation of harmful vapors emitted during epoxy application. Adequate airflow helps disperse these fumes, reducing the risk of health issues. Additionally, wearing protective gear such as gloves, goggles, and a respirator is essential to shield yourself from direct contact with the epoxy and its vapors. Gloves protect your skin from irritation or potential allergic reactions, while goggles prevent eye exposure. A respirator safeguards your respiratory system from inhaling hazardous particles.

Before starting the application, ensure the workspace is well-ventilated by opening windows or using fans. If working in a confined area, consider using a ventilation system to maintain air quality. When mixing epoxy components, follow the manufacturer’s guidelines meticulously to avoid chemical hazards. Store epoxy materials in a cool, dry place away from direct sunlight or sources of ignition. Proper storage preserves the integrity of the epoxy and minimizes the risk of accidents. During application, maintain a clean workspace to prevent slips or falls. By adhering to these safety measures, you can execute epoxy applications effectively while safeguarding your well-being.

Choosing the Right Epoxy Coating

To make an informed decision when selecting the appropriate epoxy coating, consider the specific requirements of your industrial application. Epoxy coatings come in various formulations tailored to different needs. When choosing the right epoxy coating, factors such as the type of substrate, environmental conditions, chemical exposure, and desired finish must be taken into account.

For steel surfaces exposed to harsh chemicals, consider a chemical-resistant epoxy coating. These coatings are designed to withstand corrosive substances and provide long-lasting protection. If your industrial setting experiences high temperatures, opt for a heat-resistant epoxy coating to prevent premature degradation.

Another crucial aspect is the desired finish of the coated surface. Whether you need a high-gloss finish for aesthetic purposes or a non-slip texture for safety, there are epoxy coatings available to meet these requirements. Additionally, consider the application method best suited for your project, whether it be spray, brush, or roller application.

Surface Preparation Techniques

For optimal adhesion and performance of industrial epoxy coatings, thorough surface preparation is essential. Proper surface preparation ensures that the epoxy paint adheres well to the steel substrate, creating a strong bond that enhances durability and longevity. The first step in surface preparation is cleaning. Remove all dirt, dust, grease, and contaminants from the steel surface using a degreaser or suitable cleaning solvent. This step is crucial as any residue left on the surface can interfere with the adhesion of the epoxy coating.

After cleaning, the next step is to mechanically prepare the surface. This involves roughening the steel substrate to create a profile that the epoxy paint can grip onto effectively. Methods for mechanical preparation include abrasive blasting, grinding, or sanding. Abrasive blasting, such as sandblasting, is a common and efficient technique that not only cleans the surface but also creates an anchor pattern for the epoxy to adhere to.

Once the surface is clean and properly roughened, it is essential to remove any dust or debris before applying the epoxy coating. This can be done using compressed air or vacuuming. Ensuring a clean surface at this stage is critical to prevent any imperfections in the final epoxy finish. By following these surface preparation techniques meticulously, you can optimize the adhesion and performance of industrial epoxy coatings on steel surfaces.

Maintenance Tips for Epoxy-Coated Steel

To maintain the longevity and performance of epoxy-coated steel surfaces in industrial settings, regular inspection and cleaning are crucial components. Inspecting the coated steel surfaces at regular intervals allows for the early detection of any signs of wear, damage, or corrosion. Look out for any scratches, chips, or peeling of the epoxy coating, as these can lead to the exposure of the underlying steel to corrosive elements. Addressing these issues promptly can prevent further deterioration and maintain the integrity of the coating.

When it comes to cleaning epoxy-coated steel, use a mild detergent or soap and water solution to remove dirt, grime, or chemical residues that may have accumulated on the surface. Avoid using harsh chemicals or abrasive cleaners, as they can damage the epoxy coating. Gently scrub the surface with a soft-bristled brush or cloth to avoid scratching the coating. Rinse the surface thoroughly with clean water and allow it to dry completely before inspecting it for any remaining residues.

In addition to regular inspection and cleaning, it is advisable to implement a maintenance schedule for reapplication or touch-up of the epoxy coating as needed. This proactive approach can help extend the lifespan of the coating and ensure continued protection of the steel surface against corrosion and wear in industrial environments.

Key Takeaways

- Proper surface preparation is crucial for optimal adhesion and durability.

- Choose epoxy coatings based on specific industrial needs like chemical or heat resistance.

- Follow manufacturer’s instructions for mixing, application, and storage.

- Regular maintenance and inspection prolong the lifespan of epoxy-coated steel.

- Industrial epoxy coatings enhance steel durability, resistance to corrosion, and wear.