When choosing epoxy paint for your industrial floors, consider factors like durability and chemical resistance. Different types offer varying benefits – epoxy is excellent for protective barriers against chemicals, while polyurethane is ideal for heavy foot traffic. Assess environmental demands and maintenance needs. Make sure to prep the floor surface thoroughly before application, ensuring proper mixing and even coats. Brands like Rust-Oleum and Epoxy-Coat offer industrial-grade options. Understanding these key points will help you select the right epoxy paint for your floors, ensuring longevity and performance.

Types of Epoxy Paints

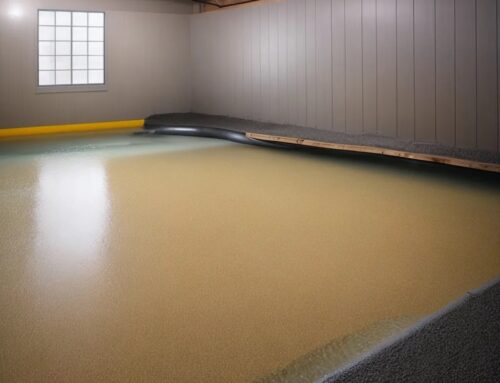

When selecting epoxy paints for floors, various types are available to suit specific industrial needs and requirements. Understanding the distinctions between industrial epoxy floor paint types is crucial for achieving optimal performance. Epoxy paints and polyurethane coatings are common choices for industrial floors, each offering unique benefits.

Epoxy paints are renowned for their durability and chemical resistance, making them ideal for industrial settings exposed to harsh substances. They create a protective barrier that shields the floor from chemicals, oils, and solvents. In comparison, polyurethane coatings excel in resisting abrasions and can withstand heavy foot traffic. When deciding between epoxy vs polyurethane for industrial floors, consider the specific demands of your environment. If chemical resistance is paramount, epoxy paints are the preferred choice. Alternatively, for areas prone to frequent abrasions, polyurethane coatings may offer better longevity.

Cost is another critical factor to consider when selecting industrial epoxy floor coatings. The industrial epoxy floor coating cost per square foot can vary depending on the type of epoxy paint chosen and the complexity of the application process. While epoxy paints may have a higher upfront cost than other alternatives, their long-term durability often outweighs the initial investment. Prioritize selecting a high-quality epoxy paint that aligns with your industrial floor’s requirements to ensure lasting performance.

Factors to Consider

Consider the specific environmental demands and performance requirements of your industrial space when evaluating factors for selecting the appropriate epoxy paint for your floors. The choice of epoxy paint should align with the conditions your floors will face, such as exposure to chemicals, heavy machinery, or high foot traffic. Chemical resistance is crucial, especially in industries where acids, solvents, or oils are present.

Look for epoxy paints specifically designed to withstand the chemicals used in your facility to prevent premature deterioration.

Abrasion tolerance is another key factor to consider. In high-traffic areas or where heavy equipment is used, the epoxy paint must be able to withstand constant wear and tear without losing its protective properties. Additionally, consider the ease of cleaning and maintenance when selecting an epoxy paint. Some formulations are easier to clean and maintain than others, leading to a longer-lasting finish.

Furthermore, assess the temperature and humidity conditions of your industrial space. Certain epoxy paints are formulated to withstand extreme temperatures or high humidity levels, ensuring their durability in challenging environments. Lastly, consider the curing time of the epoxy paint as it can affect the downtime required for application and when the floors can be fully operational again. By carefully evaluating these factors, you can choose the right epoxy paint that will provide long-lasting protection and performance for your industrial floors.

Application Techniques

To achieve a successful application of epoxy paint on industrial floors, understanding and implementing proper techniques is essential. Begin by thoroughly cleaning the floor surface to remove any dirt, oil, or contaminants. Use a degreaser and scrub brush to ensure a clean and smooth base for the epoxy to adhere to. Once the surface is clean, etch the floor using an acid solution or mechanical grinder to create a profile for better adhesion.

After preparing the surface, mix the epoxy paint according to the manufacturer’s instructions. It’s crucial to follow the recommended mixing ratios to ensure proper curing and durability. Use a roller or brush to apply the epoxy in even coats, working in small sections to prevent uneven coverage. Pay attention to the recommended thickness per coat to achieve the desired finish and performance.

When applying the epoxy, work quickly but carefully to avoid drips or uneven application. Consider using a squeegee for larger areas to ensure a smooth and consistent coating. Allow each coat to dry according to the manufacturer’s instructions before applying additional layers. Proper ventilation is key to ensuring the epoxy cures correctly.

Maintenance Tips

After applying epoxy paint to your industrial floors, ensuring proper maintenance is vital to prolong the coating’s durability and performance. To maintain the integrity of your epoxy-coated floors, it is crucial to implement a regular cleaning schedule. Sweep or dust mop the floors daily to remove any abrasive particles that could scratch the surface. For more thorough cleaning, use a neutral pH cleaner and a soft mop to prevent any damage to the epoxy coating.

When dealing with spills, especially of harsh chemicals, it is essential to clean them up promptly to prevent any potential damage to the epoxy surface. Use a soft cloth or mop with water and mild detergent to clean the affected area. Avoid using acidic or abrasive cleaners that could degrade the epoxy finish. Regularly inspect the floors for any signs of wear and tear, and address any issues immediately to prevent further damage.

Furthermore, to protect the epoxy coating from premature deterioration, consider placing mats or rugs in high-traffic areas to reduce the wear on the floors. Avoid dragging heavy equipment or sharp objects across the surface to prevent scratching. By following these maintenance tips diligently, you can ensure that your industrial epoxy-coated floors maintain their durability and aesthetic appeal for years to come.

Top Brands to Consider

When selecting epoxy paint for industrial floors, prioritize reputable brands known for their durability and performance. Consider brands like Rust-Oleum, known for their industrial-grade epoxy coatings that offer excellent chemical resistance and durability. Rust-Oleum’s epoxy paints are easy to apply and provide a high-gloss finish that can withstand heavy foot traffic and machinery.

Another top brand to consider is Epoxy-Coat, which offers a range of epoxy floor coatings designed specifically for industrial settings. These coatings are resistant to chemicals, abrasions, and impact, making them ideal for high-traffic areas. Epoxy-Coat’s products are also easy to clean and maintain, ensuring long-lasting protection for your floors.

For those looking for a more environmentally friendly option, Eco-CorFlex is a brand that focuses on producing low VOC epoxy coatings without compromising on performance. Their epoxy paints offer excellent durability and chemical resistance while being safer for the environment and the workers applying them.

When choosing an epoxy paint for your industrial floors, be sure to research these top brands and select the one that best fits your specific needs in terms of durability, performance, and environmental considerations. By investing in a reputable brand, you can ensure that your industrial floors are protected and maintain their quality for years to come.

Key Takeaways

- Consider environmental demands and performance needs for epoxy paint selection.

- Assess chemical resistance and abrasion tolerance for optimal floor protection.

- Evaluate ease of maintenance and cleaning for longer-lasting finishes.

- Pay attention to temperature, humidity, and curing time for best results.

- Choose reputable brands like Rust-Oleum or Epoxy-Coat for durability and performance.